S650 Sub-Kits & Upgrades

Industry: Automotive

PROJECTS

Scope of Work

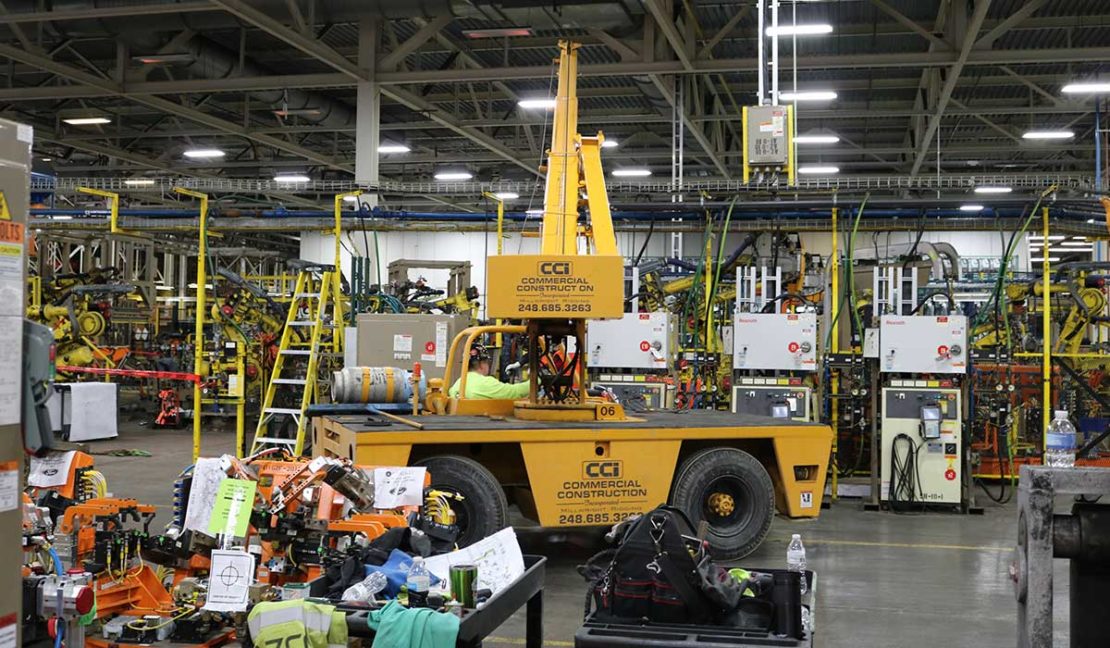

The Ford Flat Rock Assembly plant which produces the Ford Mustang and Lincoln Continental, launched multiple tooling programs during a two-week shutdown. CCI partnered with our integration client installing upgraded tooling and automation cells. Due to the aggressive schedule, our client required a contractor with industry experience, strong leadership and effective resource planning.

Serving as the general contractor, our team self-performed the removal of existing tooling, installation of new kits and installation of new cells. Work was performed on several lines throughout the plant including the hood, front apron, fenders, shotgun and boxside. In order to successfully meet the project schedule, work was performed on two shifts which maximized productivity and reduced overall downtime.

Throughout the shutdown, over 200 kits were installed and two cells were assembled. Well-organized communication and project coordination were fundamentally instrumental in the successful completion of the project. In addition, our ability to supply equipment and experienced leadership allowed our team to effectively control the project delivery, quality and safety.